Advanced materials are reshaping valve design in industries demanding high precision and reliability. As performance expectations grow, engineers increasingly rely on innovative materials to meet harsh environmental and operational challenges. This article explores how advanced materials enhance valve functionality and their impact across various applications.

Understanding Valve Functionality and Applications

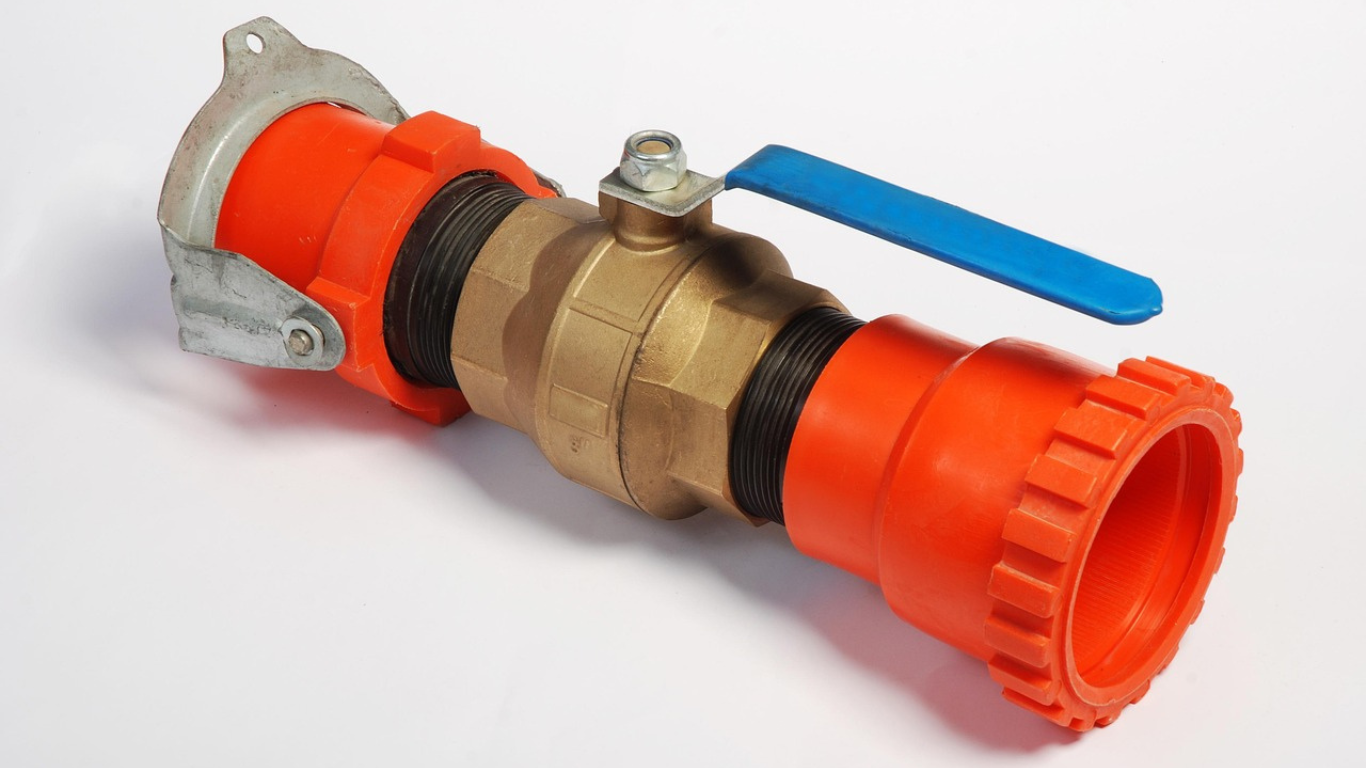

Valves are devices that control the flow of fluids, gases, or slurries within a system. Their fundamental purpose is to regulate, divert, or stop the movement of these substances, often under significant pressure or temperature variations. The diversity in valve applications sets unique requirements for materials. Valves used in chemical processing must withstand corrosive environments, while those deployed in oil and gas must endure extreme pressures and temperatures. This necessitates a blend of durability, versatility, and adaptability in material selection, influencing the design and functionality of the valves. The functionality of valves can be broadly categorized into categories such as isolation, regulation, control, and safety. Isolation valves are employed to stop flow and protect downstream equipment from damage. Control valves manage the flow rate and pressure in processes, while safety valves prevent catastrophic failures by releasing excess pressure.

The Role of Materials in Valve Design

The choice of materials in valve manufacturing significantly affects performance, longevity, and efficiency. Traditionally, valves were primarily made from metals like cast iron, bronze, or stainless steel. Technological advancements have introduced a diverse array of materials such as polyvinylidene fluoride (PVDF), ceramics, and advanced composites. These materials are engineered to provide enhanced properties such as resistance to corrosion, temperature stability, and lightweight profiles. PVDF has gained popularity due to its excellent thermal stability and chemical resistance, making it ideal for applications in the pharmaceutical and food industries.

Benefits of Advanced Materials

The use of advanced materials in valve design offers key advantages in performance, durability, and cost efficiency. Lightweight construction allows for easier installation and reduces stress on piping systems, extending service life and lowering maintenance needs. These materials provide excellent corrosion resistance, which is important in demanding sectors like oil and gas. Their versatility supports complex geometries and custom valve configurations, enabling engineers to optimize performance without being limited by traditional material constraints. Advanced materials allow for the design of complex valve types, such as the highly sought-after industrial ball valves, built for reliability and performance. The use of advanced materials in valve design enhances functionality and lifespan and supports greater efficiency and innovation across a wide range of industrial applications.

Challenges in Material Selection

Despite the benefits, selecting the right materials for valve design is not without its challenges. The intricacies of fluid dynamics and the variables of operating conditions often mean that no single material can meet all the requirements. While a material may exhibit excellent corrosion resistance, it might not withstand high temperatures or pressures. This necessitates careful consideration of the environment in which the valve will operate and ongoing innovation in material science to meet these challenges. Economic factors play a significant role in material selection. Advanced materials can often come with increased manufacturing costs, which can impact the project budget.

Emerging Trends in Valve Design

The landscape of valve design continues to evolve, largely driven by advancements in materials technology. Emerging trends such as sustainability and smart technology integration are reshaping how valves are manufactured, sold, and maintained. Sustainability has become an imperative as industries are increasingly held accountable for their environmental impact. As a result, there is a growing emphasis on recyclable materials and those that promise a reduced carbon footprint during production. The integration of smart technologies enhances the functionality of valves, allowing for real-time monitoring and control. This innovation improves the precision and reliability of fluid control and significantly reduces operational costs.

The Future of Valve Design and Materials

The future of valve design hinges on expanding our understanding of material science alongside engineering innovation. New materials, such as nanomaterials and bio-based polymers, promise to offer enhanced performance currently unattainable. These materials could lead to valves with exceptional physical and chemical properties, suitable for even the most demanding applications. As computing capabilities and simulation technologies improve, engineers will be able to model and predict valve performance under various conditions. This predictive capability can enhance the design process, enabling rapid prototyping and iterative testing that pushes the bounds of traditional valve design and usability.

The use of advanced materials is driving greater efficiency, durability, and innovation in valve design. While challenges in material selection remain, ongoing developments in material science and engineering continue to unlock new possibilities, ensuring valves meet the evolving demands of modern industry.

Article received via email