High-performance lasers turn complex manufacturing tasks into clean, repeatable workflows. You can cut intricate geometries, join dissimilar metals, texture surfaces, and mark parts that face harsh conditions. The right setup raises throughput, protects quality, and trims scrap. With smart fixturing and real-time monitoring, teams hit tight tolerances at scale. The four uses below highlight where lasers deliver fast payback and consistent results.

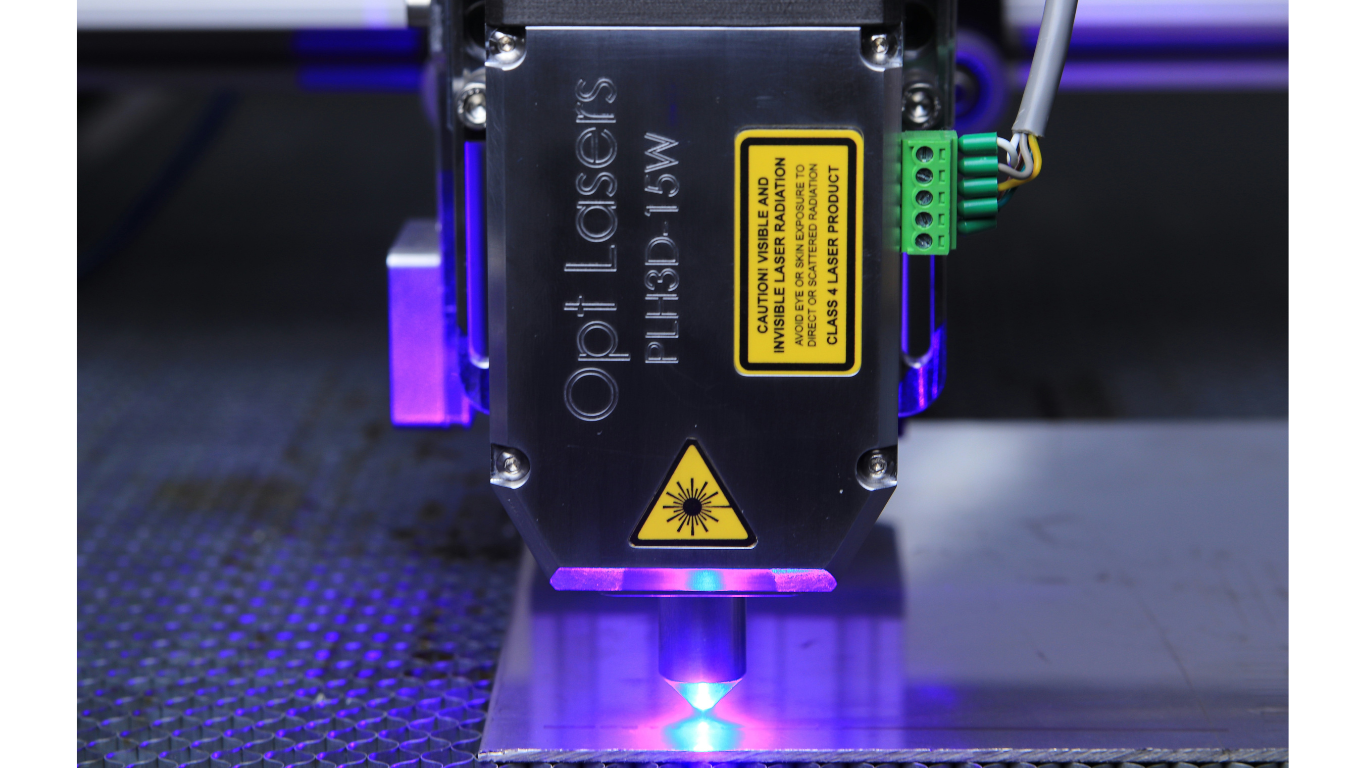

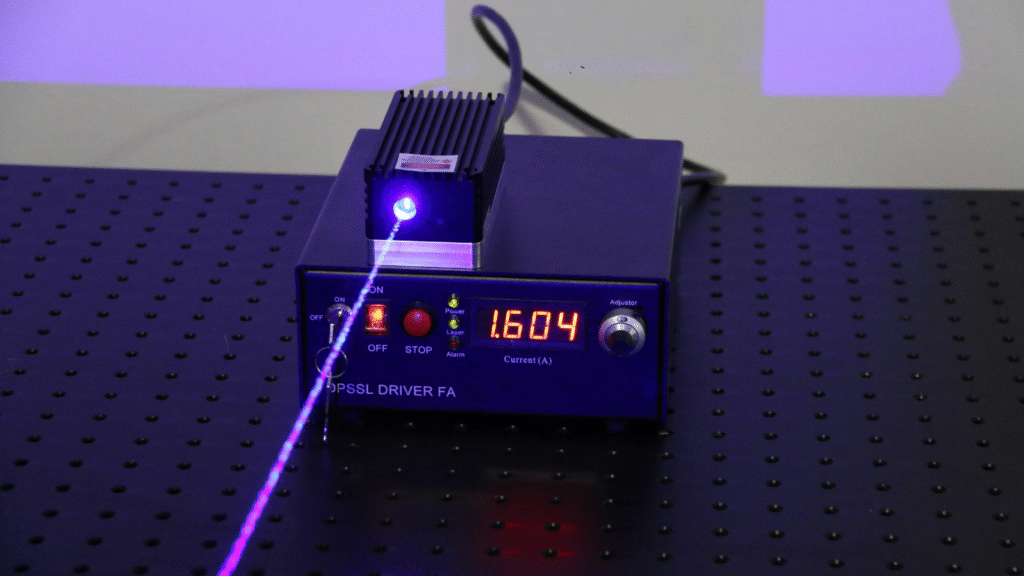

Precision Cutting and Micromachining

Lasers slice metals, polymers, ceramics, and composites with narrow kerfs and crisp edges. Short-pulse and ultrafast sources remove material without heat-affected zones that compromise fatigue life. You can drill microvias, skive battery foils, and trim medical stents in a single cell. Shops report kerf widths under 20 micrometers on thin metals, which helps pack more features into the same footprint. Consistent beam quality keeps features uniform from the first part to the thousandth. CAM toolpaths that match pulse energy, spot size, and feed rate unlock tight corner radii and burr-free edges. When you pair machine vision with part datums, the cell measures, corrects, and fires in one pass.

Welding and Joining for Throughput

Fiber and disk lasers join stainless, aluminum, copper, and mixed stacks in seconds. The concentrated energy boosts travel speed and lowers distortion, so downstream straightening drops. Teams verify weld integrity with nondestructive shearography testing methods to catch subsurface defects before they spread. Real-time keyhole monitoring and coaxial cameras flag porosity or underfill, which lets operators tweak focus or travel speed on the fly. Battery tabs, EV motor hairpins, and thin-gauge housings benefit from narrow seams and minimal rework. With proper shielding and joint prep, laser welding supports lean cells that cut cycle time across an entire line.

Surface Treatment, Texturing, and Marking

You can harden surfaces, strip coatings, and texture friction patterns without chemicals. Laser texturing adds micro-dimples that hold lubricant and lower wear on gears and seals. Engineers tune patterns by adjusting pulse duration and overlap, then validate friction or flow gains with quick bench tests. Marking cells etch permanent IDs that survive heat, abrasion, and solvents, which supports cradle-to-grave traceability. Modern fiber systems mark codes in under one second, so serialization keeps up with conveyors. When you embed verification cameras, the line reads each code and rejects nonconforming parts before packing. That closed loop protects audits and speeds recalls if they ever arise.

Additive, Repair, and Tooling Refresh

Directed energy deposition and powder-bed fusion build or rebuild parts with precise heat input. You can restore turbine tips, die corners, and mold gates with less scrap than cut-and-braze methods. Hybrid machines switch between milling and laser cladding in one setup, which shortens lead times for short runs and spares. Engineers lock in recipes that balance bead height, hatch spacing, and preheat so geometry lands on spec. Thermal models guide parameters for thin webs and overhangs, then in-process sensors confirm melt pool stability. The same platform can use texture tooling to improve part release and reduce post-processing steps.

High-performance lasers pay off when you align process recipes, fixturing, and inspection from day one. Start with a pilot cell on a high-mix product, capture real cycle data, and lock best practices into standard work. Keep your monitoring tight, and your line will deliver clean edges, strong joints, durable surfaces, and legible marks without slowing production.

Article received via email