Inventory management plays a major role in how smoothly a business operates. When inventory becomes disorganized, everything from customer service to financial planning can suffer. Lost items, inaccurate counts, and inefficient storage systems often lead to wasted time, higher costs, and missed opportunities.

Bringing order to your inventory helps create a more predictable workflow, supports better decision-making, and gives your team the clarity they need to stay productive. With the right strategies, any business can transform a cluttered stockroom into a well-structured, efficient system.

Creating a Logical Storage System That Supports Daily Operations

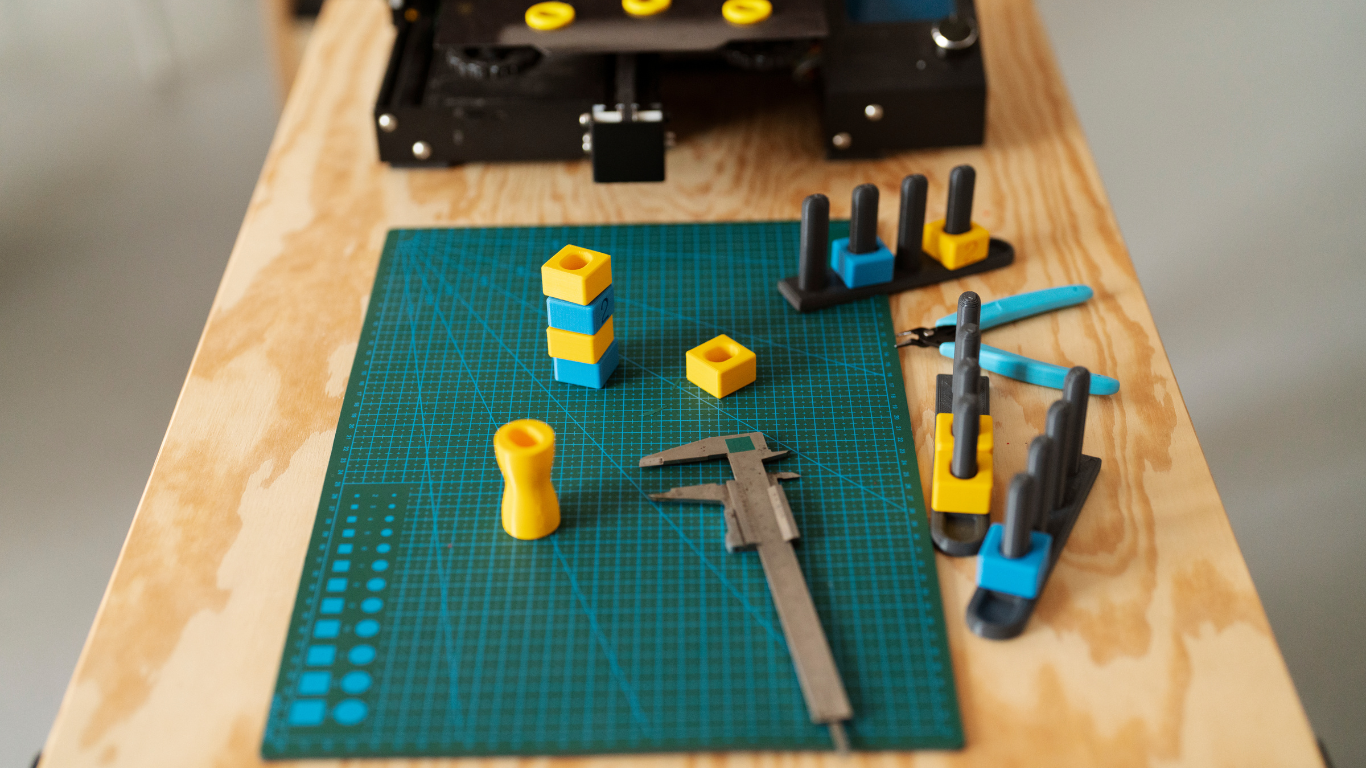

A strong inventory system begins with thoughtful organization. Grouping items by category, size, frequency of use, or product type helps create a layout that matches how your team works. When employees know exactly where to find items, they move faster and make fewer mistakes.

Businesses with growing inventory often explore flexible options to expand their storage capacity. Some companies consider solutions tailored to specific areas, such as Oakleigh storage needs, when reorganizing their systems. Additional space allows teams to sort items more effectively and avoid overfilled shelves. With clear pathways and accessible bins, the storage area becomes functional rather than chaotic.

Labeling remains equally important. Clear, visible labels on shelves, containers, and drawers prevent confusion and allow new staff to adapt quickly. A logical structure that mirrors company workflows creates smoother operations and less downtime.

Using Digital Tools to Track Stock and Prevent Errors

Technology plays a major role in keeping inventory under control. Digital tracking systems offer real-time visibility into stock levels, so businesses always know what they have on hand. Barcode scanners, cloud-based software, and automated alerts reduce the likelihood of human error and help teams avoid duplicate orders or unexpected shortages.

A strong system improves forecasting. By examining purchasing patterns and seasonal shifts, software helps businesses plan their inventory more effectively. Understanding trends allows managers to adjust orders, manage cash flow, and avoid excess stock that sits unused.

For small businesses, even a basic spreadsheet, updated consistently, creates clarity. What matters most is regular maintenance. When everyone follows the same system, information stays accurate and useful.

Streamlining Workflows Through Clear Processes

Inventory control improves when a business sets consistent procedures for receiving, storing, and distributing items. Start by establishing a dedicated area for incoming stock. Items should be counted, inspected, and logged before reaching storage shelves. This prevents mix-ups and ensures accuracy from the beginning.

A first-in, first-out approach (FIFO) helps reduce waste for items with expiration dates or limited shelf life. Even for non-perishable goods, FIFO ensures older products circulate first, keeping stock fresh and relevant.

Conducting Routine Audits to Maintain Control

Inventory control is not a one-time project but an ongoing process. Routine audits help businesses identify discrepancies, uncover inefficiencies, and correct issues before they grow. Full physical counts performed quarterly or annually provide a complete picture, while smaller cycle counts conducted weekly or monthly maintain accuracy throughout the year.

If certain items frequently go missing, get damaged, or remain overstocked, the company can adjust procedures or purchasing habits. These insights lead to better planning and less waste.

Keeping detailed records simplifies tax reporting, budgeting, and compliance. With accurate data, businesses can demonstrate accountability and financial stability when needed.

Keeping the Workspace Clean and Easy to Navigate

A clean inventory space supports both efficiency and safety. Cluttered aisles, overloaded shelves, and disorganized bins slow down workflows and increase the risk of accidents. Maintaining a tidy environment ensures that employees can move safely and complete their tasks without obstacles.

Implement a simple cleaning schedule that includes sweeping floors, clearing pathways, and returning stray items to their proper locations. The more frequently the area is maintained, the easier it becomes to keep under control.

Clear signage helps reinforce organization. When employees can follow visual cues, they waste less time searching for items and reduce misplacements.

Building a Culture That Values Organization

Even the best inventory system fails without team participation. Training employees on proper storage procedures ensures consistency. Encourage staff to follow labeling guidelines, respect workflows, and report issues when they arise.

When employees understand the purpose of inventory organization, they become more invested in keeping the system efficient. Celebrate improvements and involve the team when updating processes. Small efforts create a stronger, more organized business environment.

Transforming inventory chaos into control takes planning and consistent effort, but the benefits reach every part of a business. With clear systems, smart storage, and strong teamwork, inventory becomes a reliable asset rather than a daily challenge.

Article received via email