Commercial construction projects demand precision, speed, and adaptability. When builders need custom components for mechanical systems, or proprietary building solutions, traditional manufacturing timelines often create bottlenecks that delay entire projects. Rapid prototyping through injection molding has emerged as a practical solution, allowing builders to test designs, refine specifications, and move into production.

For commercial builders operating in North Carolina, access to local injection molding capabilities offers distinct advantages. Regional manufacturers provide faster turnaround times, direct communication with engineering teams, and the flexibility to adjust designs based on real-world testing.

Understanding Injection Molding and Rapid Prototyping

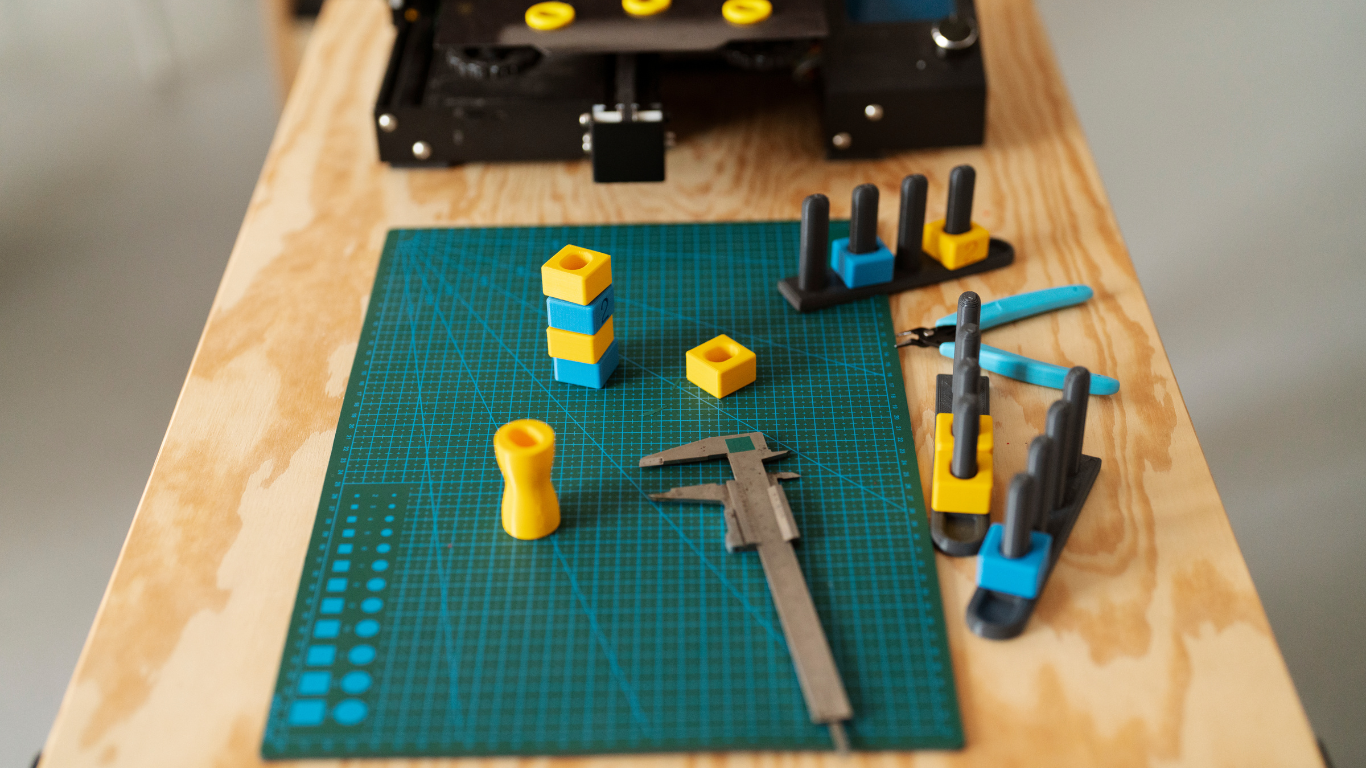

Injection molding is a manufacturing process where molten plastic is injected into a custom-designed mold cavity. Once cooled, the part is ejected, creating precise, repeatable components. The process works well for everything from small connectors to large housing units, and the versatility of materials means builders can specify plastics with specific thermal, chemical, or structural properties.

The process typically unfolds in stages. First, the builder provides specifications and design requirements. Engineers then develop a prototype mold or use additive manufacturing to create initial samples. After testing and any necessary design modifications, the final mold is produced for full-scale manufacturing. This iterative approach catches design flaws early, when they’re still inexpensive to fix.

Custom Building Components That Benefit from Injection Molding

Commercial construction involves countless plastic components, many of which require customization to meet project specifications. HVAC systems, for instance, often need specialized duct connectors, mounting brackets, or airflow control components that standard off-the-shelf parts can’t accommodate.

As commercial buildings become smarter and more energy-efficient, the need for custom enclosures and mounting solutions grows. Injection molding North Carolina facilities can produce these components with the precision and material properties required for long-term performance in demanding environments.

The Regional Advantage of Working with North Carolina Manufacturers

Geography matters in manufacturing partnerships. Working with injection molding North Carolina companies provides commercial builders with several practical benefits that out-of-state suppliers simply can’t match. Transportation time shrinks dramatically when parts only need to travel across the state rather than across the country.

A North Carolina-based injection molder working with commercial builders in the region develops familiarity with the specific challenges these projects face, from humidity and temperature extremes to the regulatory environment. This contextual knowledge translates into better recommendations and fewer surprises during production.

How Rapid Prototyping Reduces Risk and Accelerates Timelines

Traditional manufacturing requires significant upfront investment in production tooling. If design problems emerge after that investment is made, fixing them becomes expensive and time-consuming. Rapid prototyping flips this equation. By quickly producing affordable samples, builders can verify designs before major investment.

The timeline benefits are substantial. Rather than waiting months for production tooling to be manufactured overseas, then discovering a design flaw that requires starting over, builders can iterate through several design versions in weeks. Once the design is finalized, production tooling can be created with confidence, knowing the parts will perform as expected.

Integration with Commercial Building Systems

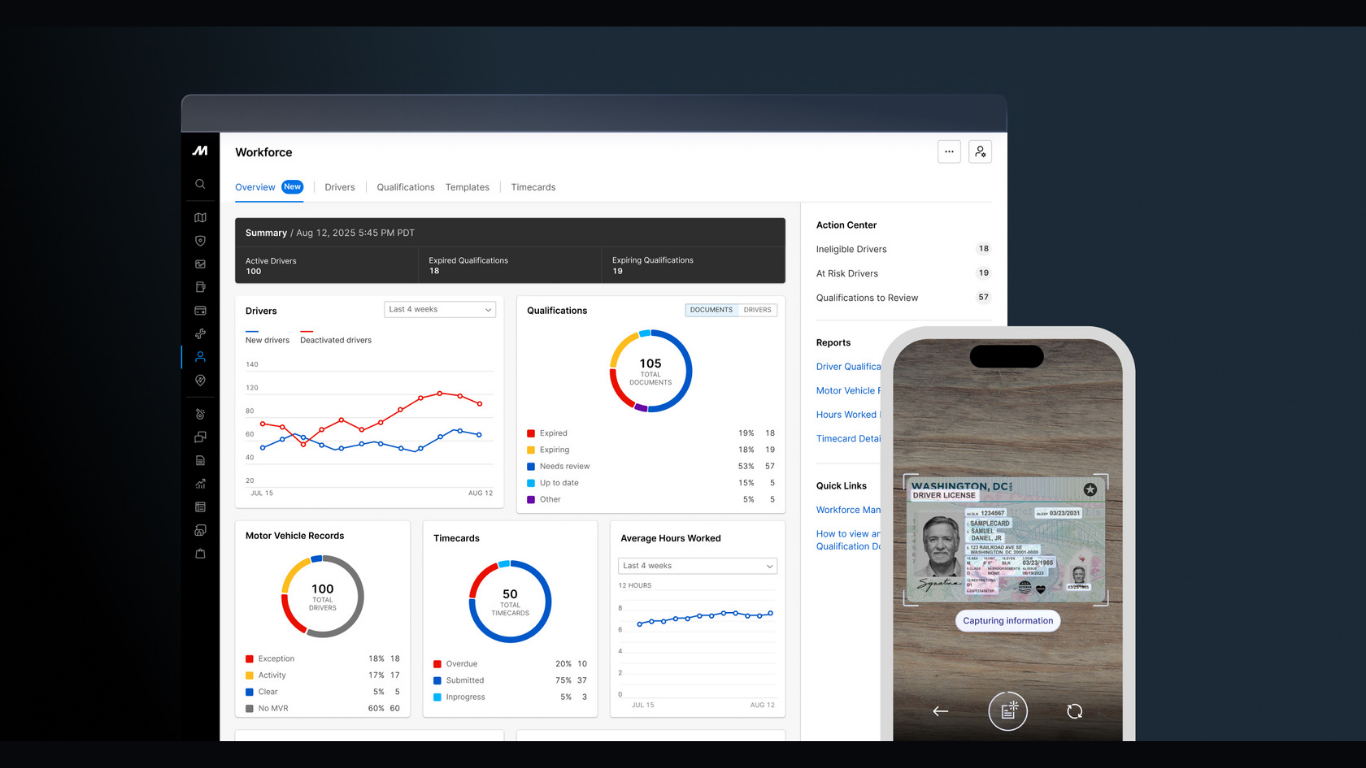

Today’s commercial buildings incorporate sophisticated control systems, energy management technologies, and smart building capabilities. Rapid prototyping with injection molding North Carolina providers allows builders to develop the exact parts these advanced systems need.

Advanced HVAC systems, such as VRF, dedicated outdoor air, or geothermal setups, may require custom parts for optimal installation and performance. Water conservation systems, renewable energy installations, and other sustainable building features present similar opportunities for custom component development.

Making the Partnership Work

Builders should engage with manufacturers early in the design process, when input on manufacturability can prevent problems later. Experienced injection molders can suggest design modifications that reduce costs, improve part strength, or simplify production without compromising functionality.

Understanding lead times aids project planning, as prototype development typically takes days to weeks depending on complexity. Once approved, production tooling may require several additional weeks before full manufacturing begins. Factoring these timelines into project schedules prevents last-minute rushes that can compromise quality or inflate costs.

A Practical Path Forward

Commercial builders face constant pressure to deliver projects faster, cheaper, and better. Rapid prototyping through regional injection molding capabilities provides a practical tool for meeting these demands. The ability to quickly develop, test, and refine custom components reduces risk while accelerating timelines.

For builders working on projects that require specialized parts or innovative building solutions, exploring partnerships with experienced injection molding manufacturers makes good business sense. The combination of technical expertise, regional proximity, and flexible production capabilities creates opportunities to solve problems that traditional manufacturing approaches can’t address efficiently.

Article received via email