Heavy-duty ceramic tile fits production lines, kitchens, and washdown rooms. The floor acts like safety equipment. When it’s specified and installed well, it reduces everyday risks like slips, trips, and surface breakdown. In busy spaces, that reliability matters.

Safety comes from parts together, surface, layout, joints, and transitions into drains. When they line up, the floor stays grippy and flat.

Slip Resistance You Can Measure

Slip resistance belongs in the spec with numbers that can be checked. A “non-slip” label rarely predicts how the surface behaves after water, oil, or dust hits it.

ANSI A326.3-2021 offers a benchmark by testing the dynamic coefficient of friction (DCOF) for slip safety, including wet conditions. A 2024 technical bulletin from Creative Materials Corp. describes it as a repeatable way to compare surfaces.

Set a target range, then apply it by zone. Dry aisles can differ from wash areas, and traction stays aligned with risk.

Texture, Channels, And Water Management

Traction drops fast when liquid sits on the surface, so the floor should move water toward drains instead of holding puddles. In wet lanes, pairing drainage planning with anti-slip industrial tiles can cut down slip risk without relying on mats that creep. Texture works best when it has direction.

Deep relief can hold grime, so balance grip with cleanability. Micro-texture, tight joints, and drains can beat a bold pattern that holds grease in every groove.

Layout choices matter. Run joints so squeegees can push liquid toward low points, and keep slopes so carts do not wobble.

Movement Joints That Keep Floors Flat

Concrete shifts from temperature swings, shrinkage, and loads, and tile does not like being forced to follow that motion. When movement has no place to go, the floor can crack or buckle, creating edges that trip people.

LATICRETE’s LATAPOXY 2000 technical data warns that leaving out movement joints can lead to cracking and breakage in grout joints and tile. That is more than an appearance problem – broken joints become water paths and uneven edges.

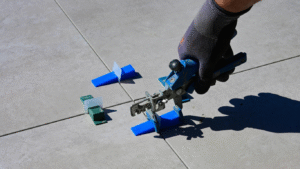

Treat movement joints as planned features, not “gaps.” Put them at perimeters, around columns, at changes in plane, and where large fields get too long, then fill them with flexible material so the surface stays flush.

Uncoupling Layers For Substrate Stress

Some floors face vibration, point loads from pallet jacks, and minor slab cracking that would telegraph straight through tile. Uncoupling systems help by letting the substrate move a little without pushing that stress into the finished surface.

A Tile and Stone Journal piece on movement joints and uncoupling membranes calls them critical elements of a good tiling job, and it notes updated recommendations on movement joints. The point is clear: details control how the floor responds when the building shifts.

Transitions deserve the same attention. Use ramps or tapered thresholds where elevation changes are unavoidable, and set drain grates level with the tile so wheels and boots do not catch.

Edges, Nosing, And Trip-Safe Details

Edge protection is a quiet win. A small bevel or a trim profile reduces chipping at tile edges, which means fewer sharp corners form in high-traffic paths.

Stairs and platforms need their own plan. High-contrast nosings, consistent tread dimensions, and a texture change at the edge help people read the step before they commit weight.

Details on the wall line matter. A cove base or tight radius at floor-to-wall transitions reduces snag points for hoses and carts, and it makes washdown faster.

Cleaning, Grout Choices, And Long-Term Traction

A surface on day 1 can turn slick if cleaning leaves a film or soils bake into the texture. Match the surface pattern to the tools and chemicals used on site, then check that routine cleaning reaches every corner.

Grout and joint design shape both hygiene and traction. Narrower joints reduce catch points for wheels, and stain-resistant grout options help keep the surface from getting patchy in spill zones.

A simple inspection rhythm keeps small issues from turning into incidents:

- Check for loose tiles, lippage, or chipped edges in main walk paths.

- Clear drains and confirm water flows to them without pooling.

- Record fixes and follow up on the next walk-through.

Ceramic tile can be a strong safety choice when the spec and install details match the space. Traction testing, smart drainage, and planned joints work together.

When a floor stays flat, readable, and cleanable, crews spend less time fighting the environment and more time doing the job. That performance comes from picking the right features early and keeping a steady maintenance routine.

Article received via email