Walk through a state‑of‑the‑art impact extrusion plant today and the first thing that stands out is the rhythm. Presses hit with steady force, parts move in tight sequences, and robots glide between stations with little wasted motion. The work still feels physical and grounded in metal, but it now runs on a layer of data, automation, and quiet intelligence that did not exist a decade ago.

This shift matters for OEMs who rely on aluminum and steel components that arrive on time, hold tolerance, and perform under stress. Robotics and AI no longer sit at the edge of the process; they now sit at the center of how advanced manufacturers deliver consistent metal extrusions at scale.

Smarter Press Cells That Run Faster and More Consistently

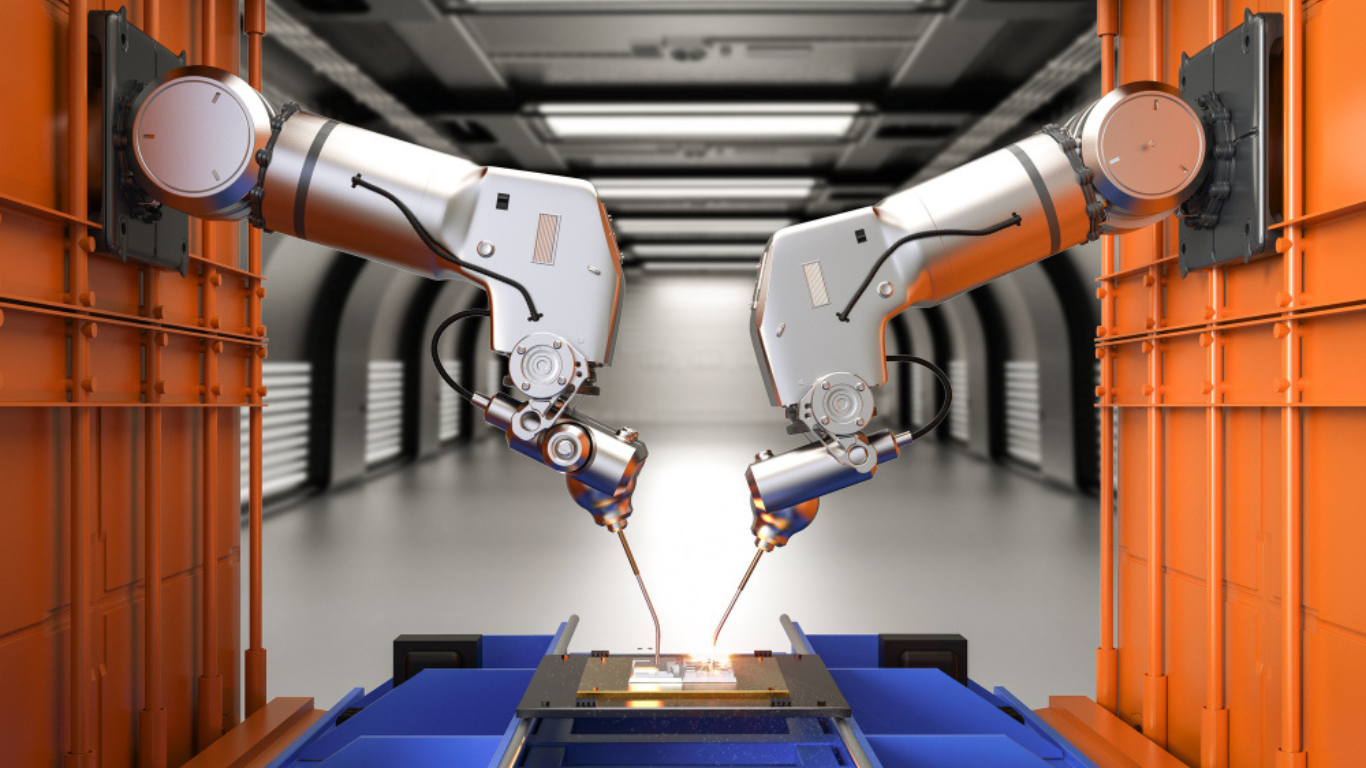

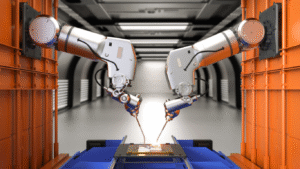

The heart of any impact extrusion operation is the press line, and this is where robotics shows the most visible impact. High tonnage presses now pair with robotic loading and unloading that keep parts moving at a pace few manual lines can match.

Instead of operators wrestling with hot slugs and finished parts, robots feed the die, clear the press, and hand off to downstream stations with exact timing every cycle. That consistency stabilizes throughput, protects tooling, and trims the small process hiccups that quietly steal hours over the course of a week.

Pre‑Processing and Handling That Protect Each Impacted Part

Robotics and AI‑driven controls keep that preparation tight across thousands of cycles. Sensors track temperature, lube coverage, and position, while software adjusts in real time to keep the process inside a narrow window. That shows up in very tangible ways:

- More consistent metal flow and fewer “mystery” defects

- Less variation in wall thickness across large runs

- Smoother transitions when parts move from metal extrusions into machining, heat treat, or assembly

When the front end of the process is this disciplined, the rest of the line simply has fewer fires to put out.

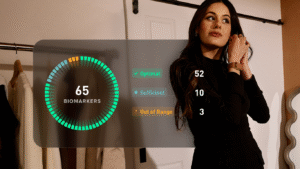

Vision Systems That Catch Problems Long Before the Customer Does

One of the biggest shifts inside advanced metal plants is the rise of in‑line vision and inspection. Cameras and sensors now sit directly on rotary transfer machines and finishing cells, watching every part the way a seasoned inspector would, only at high speed and without fatigue.

AI models learn what a good part looks like for a specific program and flag anything that drifts from that standard. Instead of catching issues at final inspection or, worse, on a customer’s receiving dock, the system picks up trends early: a slight shift in dimension, a repeating surface defect, a tool wear signature that is just starting to show.

Automation That Keeps People on the Work That Matters

A technician who once tended a single press now watches an entire automated cell, using real‑time dashboards and alerts to step in where human judgment adds the most value. Another moves from a traditional operator role into a hybrid job that blends mechanical ability with basic programming and troubleshooting.

That mix of automation and human expertise helps manufacturers hold onto knowledge of how a certain alloy behaves, how to react to an unusual noise, while letting machines handle the work that demands perfect repetition. For OEM customers, that balance shows up as stable output backed by teams who still understand the craft behind the process, not just the dashboards.

End‑to‑End Solutions Instead of Fragmented Supply Chains

One of the quieter but more important effects of robotics and AI is how they support more vertically integrated operations. When a single facility handles engineering, tooling, impact extrusion, machining, heat treating, coatings, and inspection under one roof, automation becomes the glue that holds all of those steps together day to day.

Digital traceability follows each part from slug to finished component. Plant‑wide systems schedule work, track performance, and surface bottlenecks so teams can fix problems where they start instead of chasing symptoms downstream.

A Practical Path to Stronger, Lighter, More Efficient Parts

At the end of the day, robots and AI matter in this industry for simple, practical reasons. They help manufacturers deliver parts that are lighter yet strong, hit tighter tolerances right off the press, and move from raw slug to finished component with less waste and less drama.

. In a market where every program faces pressure on cost, timing, and performance, partnering with a metal extrusion supplier that treats robotics and AI as everyday tools, not marketing buzzwords, becomes a quiet competitive advantage.

Article received via email