Companies that take care of workers prevent disruptions, reduce costs, and win trust. Safety is a system you build into every choice, from layout to leadership.

This article looks at seven ways organizations protect people while meeting sustainability goals. The aim is simple – safer work, fewer injuries, and better outcomes for everyone.

Designing Safe Workplaces From Day One

Sustainable companies start with prevention. They design spaces that remove hazards, control exposures, and make safe behavior the easy choice.

Reducing risk begins at the whiteboard, not after an accident. When teams map tasks step by step, they can place tools, lighting, and signage where workers actually need them – and they can consult an accident and injury law firm to understand legal risk while improving controls. The result is fewer weak spots during busy shifts.

Good design plans for change. As equipment, staffing, and demand shift, the workplace should support quick reconfiguration without losing safety barriers. Modular guards, standardized lockout points, and visual management keep protections visible and durable.

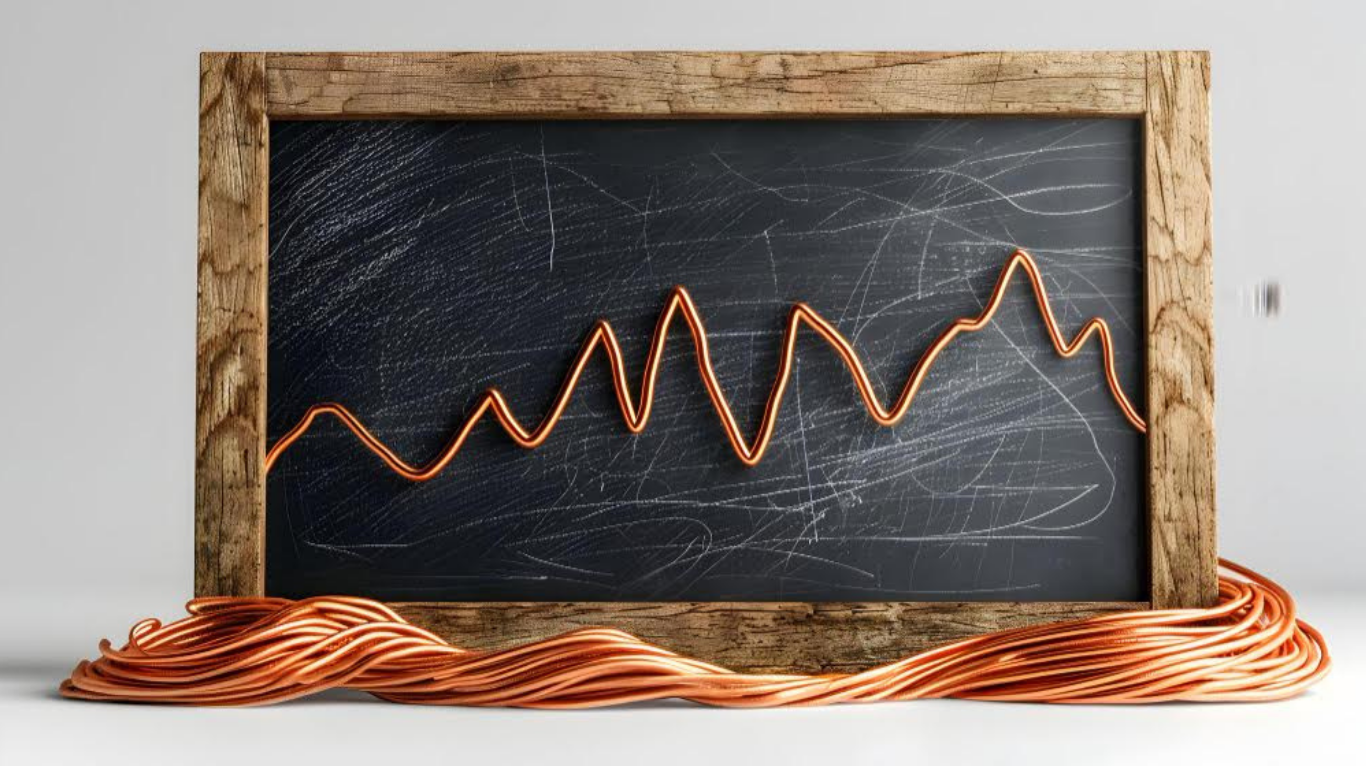

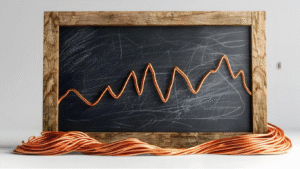

Tracking Safety Metrics That Matter

What gets measured gets managed. Leading companies track lagging indicators like recordable injuries, and track leading indicators such as near misses, inspection completion, and corrective action aging.

Recent national data underscores the stakes. Federal labor statistics reported 2.5 million injury and illness cases in private industry in 2024, a 3.1 percent decline from 2023, highlighting the value of sustained prevention.

Metrics should be simple, timely, and actionable. Teams review them in daily huddles, celebrate fixes, and remove blockers. Leaders ask two questions: What did we learn yesterday, and what will we do differently today?

Empowering Workers Through Training And Voice

Training is not a slide deck – it is practice. Sustainable companies teach with short, hands-on drills at the job site.

They treat employees as experts. People closest to the work know where safeguards fail and where shortcuts tempt. A structured suggestion system and routine walkarounds turn that insight into improvements that stick.

- Microlearning at shift start

- Peer-led refreshers after near misses

- Quick-reference cards at the point of use

Learning From Incidents Without Blame

When something goes wrong, the goal is learning. Were procedures clear? Were the tools fit for purpose? Were the signals confusing?

An OSHA update noted employers submitted about 370,000 annual summary reports, and the agency posted partial data from over 732,000 incident log and report records, giving the public a broader view of hazards and patterns. Organizations can mirror that openness by sharing lessons across sites.

Close calls deserve the same energy as injuries. Quick, respectful debriefs capture context while memories are fresh. Then teams turn insights into specific controls, due dates, and verification checks.

Supporting Total Worker Health

Sustainable companies reduce exposure to noise, chemicals, and heat, and they support sleep, movement, and mental health. Safer tasks and healthier routines create stronger bodies and better focus.

Benefits work best when they are simple. On-site stretching, clean hydration stations, and quiet rooms for short breaks help people reset. Access to trusted counseling and clear time-off rules reduce presenteeism and burnout.

Offer fit-for-duty evaluations after illnesses or injuries, and tailor return-to-work plans. When people feel cared for, they report symptoms early and recover better.

Designing Schedules And Staffing For Safety

Fatigue is a hazard like any other. Sustainable companies set shift lengths, rotations, and handoffs to preserve alertness. The staff should demand that people are not forced into risky overtime.

Workflows should match human limits. Complex tasks happen when attention is sharp. Repetitive tasks rotate to avoid strain. Breaks are planned, protected, and used – not traded away.

Technology can help, but should not overpromise. Wearables and sensors can flag fatigue or unsafe movements, yet they complement rather than replace good staffing and realistic deadlines.

Using Procurement And Partners To Raise Standards

Safety extends beyond your walls. Vendors, contractors, and transport partners shape risk every day. A sustainable company sets clear requirements and audits against them.

Contract language should spell out safety expectations, reporting rules, and stop-work authority. Prequalification checks and site orientations ensure partners meet your bar before they arrive.

Reward the right behavior. Share best practices, host joint drills, and recognize suppliers who raise the bar. Your purchasing power can pull safer designs and materials across the value chain.

Sustainable safety is a journey, not a finish line. Start with design, listen to workers, and learn from every close call.

Keep it simple, consistent, and human. When people trust the process, they bring their best to work and go home healthy.

Article received via email