Scales are a big part of many industrial processes, ranging from manufacturing to food production. Their ability to measure weight with precision will guarantee that companies can maintain quality and consistency in their products.

Even minor discrepancies can impact the final output, and that’s why the need for accurate scales is non-negotiable. This article dives into the role that scales play throughout the industry, with a focus on their applications in production and quality control.

Types of Scales Used in Industrial Settings

The diversity of scales used in industry is vast, catering to different needs across sectors. Electronic scales have rapidly become standard due to their accuracy and ease of use. Their digital displays allow for quick readings, whereas advanced models offer data logging and connectivity for monitoring purposes. Traditional mechanical scales still serve a role in settings where electronic devices may not be feasible.

Specific industries require specialized scales. Food production uses scales designed to meet sanitary standards. Chemical industries may rely on explosion-proof scales due to hazardous environments, whereas other sectors might focus on portability for on-site measurements.

The Importance of Calibration

Regular calibration schedules help to identify and rectify drift, which can occur due to temperature fluctuations or mechanical wear. In production settings, scaled inaccuracies can introduce quality control issues, leading to costly errors in manufacturing processes and product inconsistencies.

With stringent calibration protocols, companies mitigate risks associated with inaccurate readings. Calibration involves the use of certified weights, such as cast iron scale weights, to verify that scales produce reliable results. Scales that are regularly calibrated reinforce trust with clients and stakeholders, proving that a company takes its product quality seriously.

Scales in Quality Control Processes

Scales are extensively utilized during the quality control phase to verify product weight, which can be a critical indicator of quality. Weights that fall outside predetermined specifications can signal problems with portion control or ingredient ratios in food production. Regular weighing during manufacturing enables timely interventions, helping prevent the shipment of subpar or faulty products.

Integrating scales within the production line improves operational efficiency. By automating the weighing process, companies can reduce human error and speed up the production cycle. Companies use automated scales to gather data that can be analyzed for continuous improvement, which results in increased productivity and reduced costs.

Environmental Influences on Scale Accuracy

The accuracy of scales can be affected by temperature, humidity, and air pressure. These influences can cause inconsistencies in weighing that may go unnoticed without proper monitoring.

Electronic scales are sensitive to temperature changes, which can lead to fluctuating readings if not adequately accounted for. High humidity can cause wear on mechanical parts and affect the scale’s performance, leading to inaccuracies. To combat these effects, many industries utilize climate-controlled environments for sensitive weighing operations.

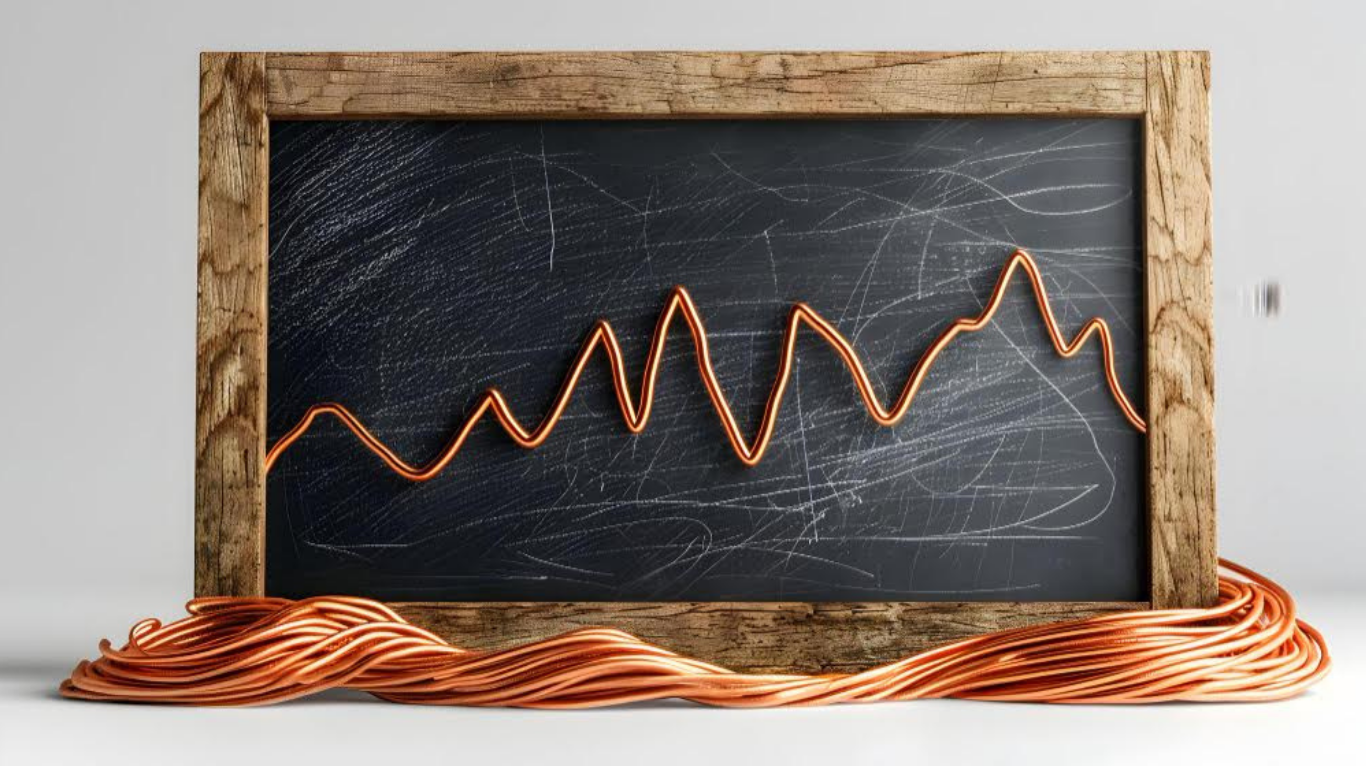

Role of Technology in Modern Weighing Systems

Smart scales now integrate with production management systems, allowing real-time data analysis and tracking of weights throughout the production process. Companies can identify trends, enabling better forecasting of production needs and quality assessments.

The advancements in software make it easier for operators to monitor and manage multiple scales across different stations. Some smart weighing systems even feature alerts and notifications for operators when a reading falls outside the set range so that immediate corrective actions can be taken.

Compliance and Regulation Considerations

Accurate weighing must meet standards set by governing bodies, as inaccuracies can result in legal repercussions and safety concerns. Businesses’ scales must comply with local and international regulations governing weight measurement accuracy. In the US, the National Institute of Standards and Technology (NIST) outlines specifications for weighing equipment to provide uniformity.

Certification processes and required calibrations guarantee that scales are consistent and trustworthy across various applications. Companies must be informed of applicable regulations and invest in scales that exceed these standards.

Future Trends in Industrial Weighing

The future of industrial weighing points toward even greater integration of artificial intelligence and machine learning. These technologies hold the potential to transform how weighing systems operate. Future scales will allow for continuous self-calibration, using data analytics to get precise measurements even in fluctuating conditions.

Automation trends suggest that scales will become more integrated within automated production lines, facilitating seamless transitions from weighing to packaging. This further streamlining aims to eradicate bottlenecks and inefficiencies present in traditional operations.

Industry scales can benefit any business from production to quality control. By understanding the types, calibrations, and regulations, businesses can optimize their operations. Maintaining accuracy through modern technology bolsters quality for higher customer satisfaction and business growth.

Article received via email