NIPPON KINZOKU CO., LTD. (Headquarters: Minato-ku, Tokyo) will strengthen sales of its “SFA Finish” carbon steel and carbon tool steel, which offer improved workability through softening, as the fifth product in its environmentally-friendly “Eco-Product” series.

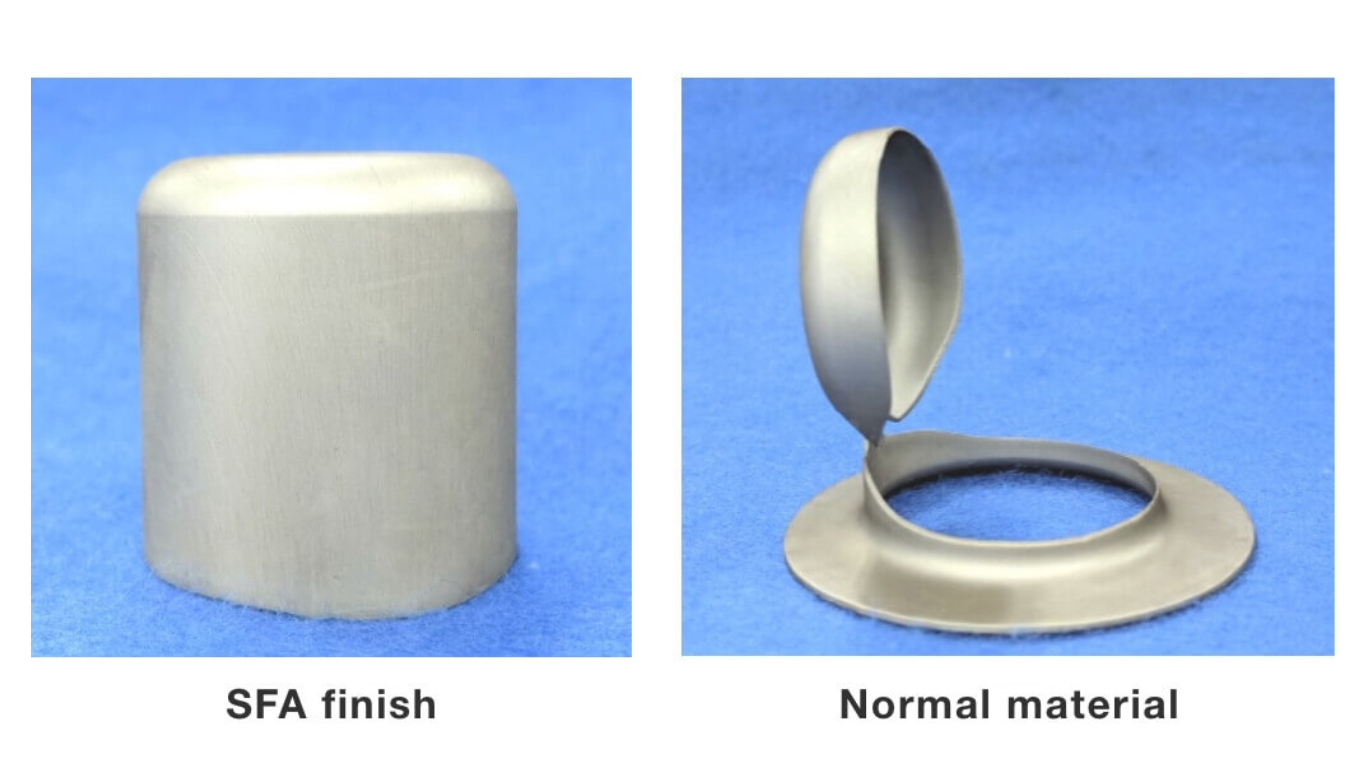

“SFA (Super Full Annealing) Finish” is our proprietary product that softens materials without altering chemical composition by optimizing manufacturing conditions. This softening enhances workability and reduces springback. Consequently, it enables process streamlining and improved yield rates, contributing to enhance energy efficiency in manufacturing processes and reduced environmental impact.

Therefore, our “SFA finish” for carbon steel and carbon tool steel is certified as an environmentally-friendly “Eco-Product” under our proprietary standards. We are committed to sustainable manufacturing through the widespread adoption of environmentally-friendly materials, aiming for net-zero CO2 emissions by 2050.

Furthermore, this product is a proprietary offering aligned with the vision of our 11th Business Plan, “NIPPON KINZOKU 2030.” Under the keyword “Near Net Performance” (achieving the performance required of the final product at the material stage), it meets customer needs. Going forward, we aim to further expand sales, primarily in the automotive sector.

Features and Benefits of SFA Finish

- Chemical Composition

Product properties are enhanced by optimizing cold rolling conditions, with no changes to the chemical composition. - Mechanical Properties

Compared to standard annealed products, it offers superior ductility while being softer (lower strength). - Processability

Its low springback ensures stable product shape after processing. - Metal Structure

The size of the spheroidal carbides is approximately 1.0 to 1.5 μm, equivalent to typical annealed finish. - Properties after Heat Treatment

The microstructure and hardness after quenching and tempering are equivalent to those of general-purpose materials.

For more information, visit the NIPPON KINZOKU website.

More related news:

Nordson Electronics Unveils 99% Yield PLP Solution for Powertech Technology, Inc.

UL Solutions Boosts Fire Testing for Advanced Battery Technology